Best quality 316 Stainless Steel Self Drilling Screws - Truss head Self-Drilling Screws – DaHe

Best quality 316 Stainless Steel Self Drilling Screws - Truss head Self-Drilling Screws – DaHe Detail:

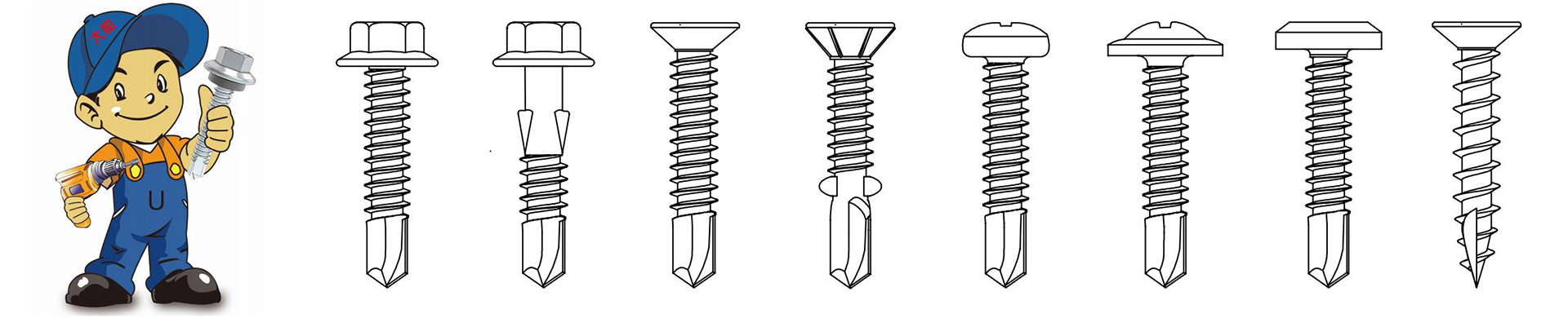

A fastener with an extra wide head, twinfast thread and self drilling point. The head is an integrally formed round washer with a low rounded top that is approximately 75% the diameter of the washer. Material including:C1022 or equivalent steel and 410 stainless

C1022

Common usage is to attach wire or metal lathe to metal studs of a thickness between 12-20 gauge.the head design offers low clearance and an extra large bearing surface.the recommended drive speed for installation is 2500 rpm.

Heat Treatment:Screws shall be quenched in liquid and then tempered by reheating to 625゜F minimum.

Hydrogen embrittlement: Lustrate hydrogen after galvanizing to avoid hydrogen embrittlement(The production from DaHe company Only)

410 stainless

Not as corrosion-resistant as the 18-8 variety but will drill through harder materials than the 18-8 screw. The same hardness gradient rule applies: material drilled should be a minimum of 10-20 rockwell hardness points less than the fastener

Heat Treatment:An ideal method of hardening 410 stainless screws is a bright hardening process,which typically involves a vacuum furnace, Another key factor affecting hardness is the chemistry of the fastener–most elements have maximum values but not minimums.This fact can contribute to hardness variance.

Usually supplied without a secondary finish

Hydrogen embrittlement: there is not Hydrogen embrittlement risk occur

Note: there is no single standard for Truss head self-drilling screws.these values are offered as a guide, deviations from these specifications may occur

Specification

|

Brand |

Solidex |

|

Product Type |

Truss head Self-Drilling Screws |

|

Material |

Stainless steel/carbon steel |

|

Drive Type |

Phillips/Six-lobe drive |

|

Product Length |

5/8″-12″/1/4″ 3/8″ 7/16″ 1/2″ 9/16″ 5/8″ 3/4″ 7/8″ 1″ 1-1/8″ 1-1/4″ |

|

Screw Diameter (mm) |

6#/7#/8#/10#/12# |

|

Thread Length |

Fully Thread |

|

RoHS |

Depend on request |

|

Finish |

Clear Zinc/Customized different color |

|

Corrosion resistance class |

C3 |

|

Product Standard |

GB/DIN/ANSI/BS/JIS |

|

Approvals |

CE |

|

Packing |

Coustomer’s Requirements |

|

OEM |

Accept customization |

|

Sample |

Free |

|

Place of Origin |

Hebei, China |

|

Suitable Use Type |

Suitable for indoor Use |

|

Manufacturer Guarantee |

1 Year Guarantee |

|

Supply Ability |

100 Ton/Tons per Day |

NOTE:

1: Drill Capacity: 8g (0.75-2.5mm of steel), 10g (0.75-3.5mm of steel)

2:Driver Type: Philips P2

3:Installation Speed: 2300-2500 RPM Max Drill Speed

Product detail pictures:

Related Product Guide:

Adhering for the theory of "quality, services, performance and growth", we have received trusts and praises from domestic and worldwide shopper for Best quality 316 Stainless Steel Self Drilling Screws - Truss head Self-Drilling Screws – DaHe , The product will supply to all over the world, such as: India, Mexico, Sweden, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.